Injection Molding Manufacturer: Innovating Product Design and Engineering Solutions

In today’s competitive manufacturing landscape, companies are continuously seeking reliable partners who can deliver top-quality, durable products. Injection molding stands out as a versatile and highly efficient process, playing a critical role in industries such as medical devices, electronics, household appliances, aerospace, and the automotive sector. HITOP, a leader in the Injection molding manufacturer industry, offers cutting-edge manufacturing innovations, product design expertise, and engineering solutions tailored to meet the specific needs of these industries. Their commitment to high-performance molds and personalized service has made them a preferred partner for businesses looking to stay ahead of the curve.

What is Injection Molding?

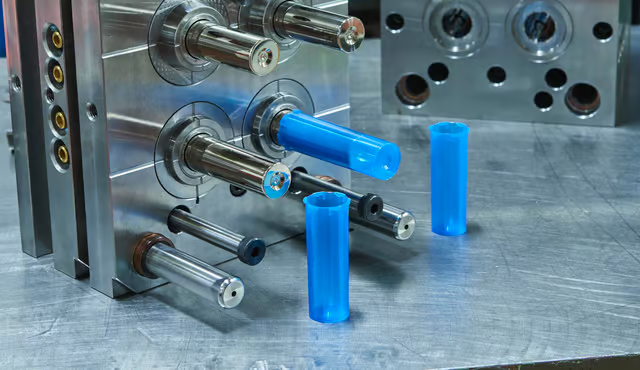

Injection molding is a manufacturing process where molten plastic or other materials are injected into a mold cavity, cooled, and then ejected to create a finished part. This method is favored for its ability to produce high-quality, precise, and consistent parts in large quantities. The versatility of injection molding allows it to accommodate a wide range of materials, including thermoplastics, thermosetting polymers, metals, and even glass.

Benefits of Injection Molding

- High Efficiency: Injection molding is known for its speed, making it one of the most efficient manufacturing processes available. Once the initial design and mold are completed, production can run continuously, producing large volumes of parts with minimal downtime.

- Precision and Consistency: The injection molding process ensures each part is made with precision, and once the mold is created, each part will be identical. This consistency is vital for industries such as medical devices, where even the slightest variation can have significant consequences.

- Reduced Waste: Modern injection molding techniques are designed to minimize waste, with the ability to reuse excess material in some processes. This makes it an eco-friendly option, especially for industries looking to reduce their environmental impact.

- Complex Geometries: Injection molding allows for the creation of highly complex and intricate designs that would be impossible or prohibitively expensive with other manufacturing methods.

- Cost-Effective: Although the initial investment in mold creation can be high, the per-unit cost of parts is low, making injection molding an economical option for mass production.

HITOP: Experts in Injection Molding

HITOP has built a solid reputation in the injection molding industry by focusing on delivering durable, high-performance molds that cater to the specific needs of its clients. Their dedication to excellence in product design, engineering solutions, and personalized service makes them a trusted partner for businesses across several industries. Here’s why HITOP stands out:

1. Manufacturing Innovations

HITOP stays at the forefront of the latest advancements in injection molding technology. Their innovative approach includes integrating automation and advanced robotics into their processes, ensuring maximum efficiency and accuracy in production. By leveraging the latest tools and techniques, HITOP can quickly scale production, meet tight deadlines, and deliver complex parts that meet stringent quality standards.

Their investment in state-of-the-art equipment enables them to handle a wide range of materials and produce parts with tight tolerances. HITOP also utilizes computer-aided design (CAD) and computer-aided manufacturing (CAM) to streamline the design process, allowing clients to visualize their products and make modifications before the mold creation begins. This reduces the likelihood of errors and accelerates the time-to-market.

2. Expert Product Design

HITOP excels in transforming ideas into reality. Their team of skilled engineers works closely with clients to develop custom product designs that meet both aesthetic and functional requirements. Whether it’s a simple household item or a highly specialized medical device, HITOP ensures that each design is optimized for manufacturability, durability, and cost-efficiency.

The design phase is critical in injection molding, as the mold itself is the most significant part of the process. HITOP’s expertise in mold design ensures that each mold is built to withstand the rigors of mass production while producing parts that are both accurate and reliable. By focusing on quality from the very beginning, they help businesses avoid costly errors and production delays.

3. Engineering Solutions Tailored to Industry Needs

Industries such as medical, electronic, household appliances, aerospace, and automotive have unique requirements, and HITOP understands the importance of delivering tailored engineering solutions. For example:

- Medical Devices: HITOP manufactures precision parts for medical devices that require strict adherence to safety and quality standards. They are experienced in working with biocompatible materials and meeting the rigorous regulatory requirements of the healthcare industry.

- Electronics: HITOP provides high-quality injection molding solutions for electronic components that require tight tolerances and heat-resistant materials. Their expertise in working with advanced polymers ensures that the parts meet the demands of modern electronics manufacturing.

- Aerospace: The aerospace industry requires parts that are lightweight, durable, and capable of withstanding extreme conditions. HITOP’s engineering team works with high-performance materials to create components that meet these specifications while ensuring safety and reliability.

- Automotive: Automotive manufacturers rely on HITOP for their ability to produce durable and complex components at a large scale. HITOP’s injection molding process ensures that each part meets the industry’s demanding standards for safety, performance, and durability.

4. Commitment to Personalized Service

At HITOP, client relationships are a top priority. They offer personalized service that goes beyond simply delivering parts. Their team works closely with each client to understand their specific needs, challenges, and goals. This collaborative approach ensures that each project is tailored to the unique requirements of the business, whether it’s creating a custom mold, optimizing production processes, or providing ongoing technical support.

HITOP’s commitment to customer satisfaction is evident in their attention to detail and willingness to go the extra mile. They offer comprehensive project management services, guiding clients through every stage of the injection molding process, from initial concept to final delivery. This level of service is particularly valuable for businesses in industries like medical devices and aerospace, where precision and reliability are paramount.

5. Durable, High-Performance Molds

A mold’s quality directly impacts the final product’s performance, and HITOP takes this aspect seriously. They use only the highest quality materials and advanced manufacturing techniques to create molds that are built to last. Whether the mold is designed for short production runs or high-volume mass production, HITOP ensures that it will produce consistent results over time.

Their rigorous testing and quality assurance processes ensure that each mold meets or exceeds industry standards. By focusing on durability and performance, HITOP helps businesses reduce maintenance costs and avoid production downtime.

Conclusion

As businesses across industries continue to seek innovative, cost-effective manufacturing solutions, injection molding remains a key technology. HITOP’s expertise in creating durable, high-performance molds, combined with their commitment to personalized service, makes them a trusted partner for companies in the medical, electronics, household appliances, aerospace, and automotive sectors. Their dedication to manufacturing innovations, expert product design, and tailored engineering solutions ensures that they can meet the unique challenges of each industry.

For businesses looking to enhance their product development processes and deliver high-quality parts to the market, HITOP offers the experience, technology, and support needed to achieve success. Whether it’s developing complex medical devices or precision automotive components, HITOP provides the injection molding solutions that help businesses thrive.

Stay in the loop for upcoming updates and alerts! Tech Trand